What is Rapid Hardening Cement (RHC)?

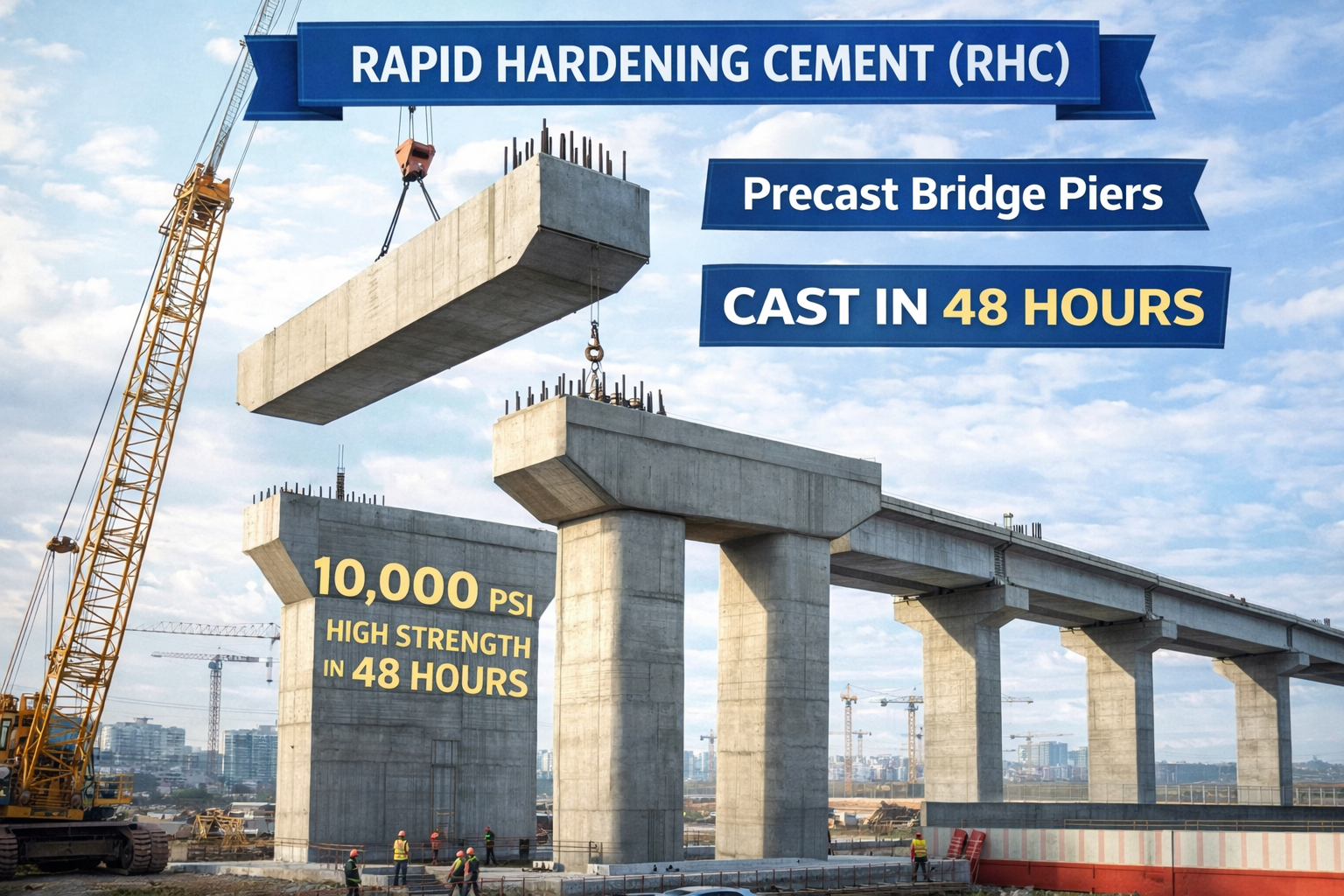

Rapid Hardening Cement (RHC) is a special type of Portland cement designed to gain strength much faster than ordinary cement, achieving high early strength within 3 to 7 days. It is made by grinding clinker more finely and increasing the proportion of C₃S (tricalcium silicate), which accelerates hydration. RHC is particularly suitable for projects requiring quick formwork removal, urgent repair works, road pavements, airport runways, and precast concrete elements, where early strength is critical. Additionally, it retains good long-term strength and durability, making it a reliable choice for both time-sensitive construction and durable structural applications.

How to Choose the Right type of RHC Cement?

Choosing the right type of Rapid Hardening Cement (RHC) depends on project urgency, structural requirements, and environmental conditions. First, assess how quickly the concrete needs to gain strength—RHC is ideal for fast-track construction, emergency repairs, or precast elements where formwork removal or load application must happen within days. Next, consider the type of structure: roads, pavements, airport runways, and industrial floors benefit from RHC due to its high early strength. Also, evaluate environmental exposure—RHC performs well in normal conditions but may require additional protection in aggressive chemical or marine environments, as rapid hydration can slightly increase permeability. Finally, choose a certified brand with consistent fineness and clinker quality, ensuring both rapid early strength and long-term durability. Proper selection balances speed, structural safety, and longevity for time-critical projects.

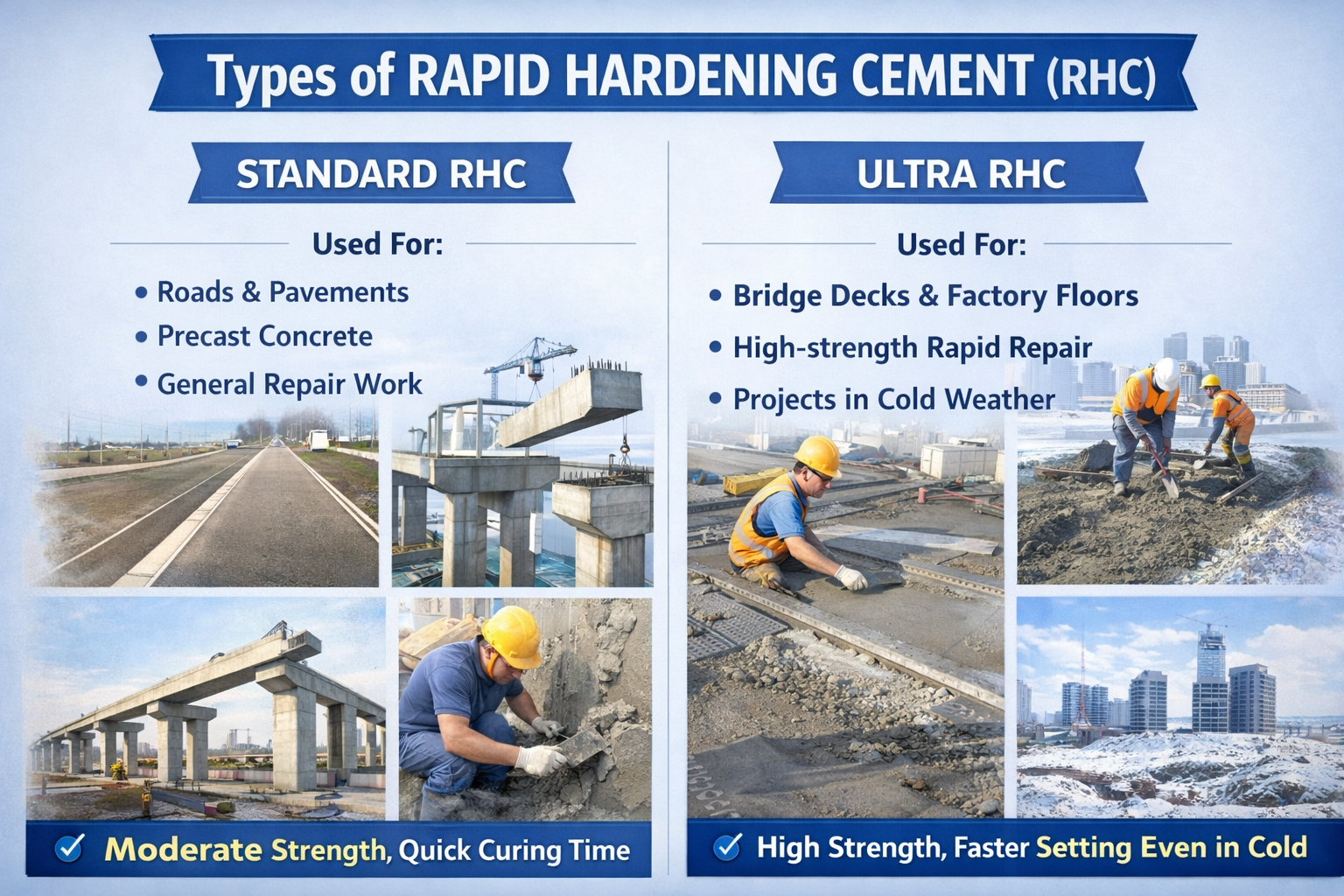

Types of RHC Cement and Their Use Cases

Standard Rapid Hardening Cement

High-Strength or Special Rapid Hardening Cement